![]()

Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

processing capacity:50-1200kg/H

Application scope:candy, hard candy

Product introduction: Full-automatic die forming hard candy making machine can produce all kinds of solid hard candy, sandwich hard candy, special-shaped hard candy, color hard candy and other hard candy

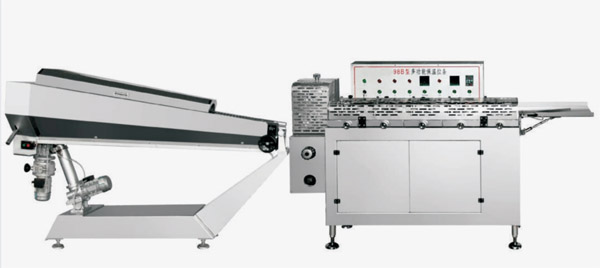

Die-forming hard candy making machine

Die-forming hard candy making machine

Hard candy: hard candy, nougat, toffee, lollipop, chocolate candy, milk candy, xylitol gum, bubble gum, suitable for pouring and stamping out different shapes of hard candy, sandy milk candy, toffee, sandwich candy, irregular shaped lollipop, flat lollipop, spiral flower candy. Cylindrical and spherical candy, milk candy, cane candy, nougat, etc

die-forming Hard candy making machinedie-forming Hard candy making machine

Full-automatic die-forming hard candy making machine

The making machine can produce various types of die hard candy.

Full-automatic hard candy die making machine can produce all kinds of solid hard candy, sandwich hard candy, special-shaped hard candy, color hard candy and other hard candy

Vacuum continuous saccharification ensures the quality of the cream. The unique molding method makes the sandwich effect good.

The production capacity can reach 200-1200 kilograms per hour. Synchronous automatic control, sandwich, uniform strip and molding. Different shapes of candy can be produced by changing the mold.

The conveying cooling system ensures the cooling effect of candy. It can produce spherical lollipops with automatic bract molding machine.

Process flow of automatic hard candy die making machine

Sugar melting - storage tank - vacuum boiling pot - cooling table - conveyor - insulation roller bed - stretching machine - candy forming machine - cooling screen - packaging machine

Main machine of die-forming hard candy making machine

Vacuum sugar cooking machine

It features automatic temperature control, high output, time-saving, short cooking time, and can manufacture the syrup with high transparency.

①.Sugar melting cooker

Batch size(L):300

Weight(kg):280

Dimension(mm):1100*1100*1700

②.Storage tank

Batch size(L):300

Weight(kg):220

Dimension(mm):740*740*1250

③.Technical parameters

Production capacity(kg/h):350-400

Heating area(m³):2.45

Steam pressure(MPa):0.7-1.0

Steam consumption(kg/h):约about100

Syrup temperature before entering(°C):110-115

Temperature after discharging(°C):135-145

Power-Fixed displacement pump(kw):0.75

Power-Vacuum pump(kw):5.5

Dimension(mm):1900*1700*2300

Machine weight(kg):800

Heat preservation batch roller and rope sizer

Purpose

It is suitable for heat insulation and pulling of sugar pastes.

Feature

It has such features as simple operation, labor saving and high efficiency.

Technical parameters

Batch roller maximum capacity(m³):0.20

Running speed(m/min):≤40

Total power(kw):7

Weight(kg):850

Multi function candy forming machine

Purpose

It is suitable for production of hard candies, gaining creamy candies, toffees and filled candies, as well as production of cushions (candy shapes varying according to customer requirements), such as: spherical, oblate, oval and other irregular shapes.

Feature

Punching and forming, stable running, high output

Technical parameters

Production capacity: w250kg/h

Total power: 2.4kw

Weight: 800kg

Dimension: 2000 x 1100 x1300mm

Candy cooling tunnel

The candy cooling tunnel can rapidly reduce the problem temperature of candy, which is a necessary machine for mass production of candy

Die-forming hard candy making Machine Working Principle

Continuous die-forming of hard candy forming: when the sugar billet is cooled to the appropriate temperature, it can be pressed forming. If the temperature is too high, the candy body is too soft, it is difficult to form, even if the molding candy block is easy to stick or deformation, such as the temperature is too low, the candy billet is too hard, the candy granules formed out, easy to produce hair darkening and missing edge broken Angle. The appropriate temperature for die-forming forming is 80-70℃, when the candy billet has the most ideal plasticity, die-forming forming is to use the characteristics of the canyd billet at this temperature, with the drawing machine or artificial candy billet stretching into strips, into the forming machine die-forming forming.

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemapManufacturer Candy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line chocolate production line chewing gum production line Popping boba production line